본문

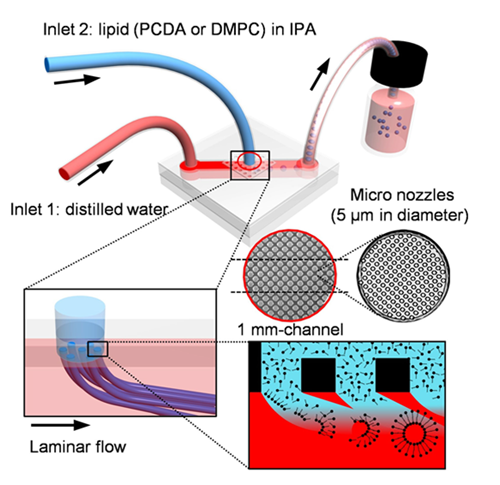

Liposome Synthesis Device

Liposome (Lipid Vesicle)

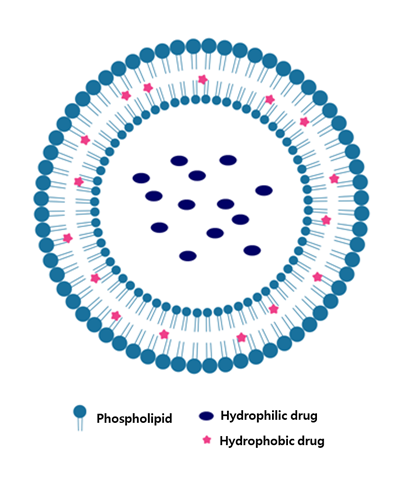

Spheres of tens of nm to several um diameter of hollow structure in which phospholipid or amphiphilic polymer consists of double layers

Vesicle Nanoparticles are synthesized by mixing fat-soluble / hydrophobic target material and phospholipid solution. Also they hold drugs, bio materials, etc. that need to be protected / separated / released from the external environment.

Hydrophilic and hydrophobic biomaterials and drugs can be loaded according to the application.

Synthesis Principle

[Synthesized Liposome]

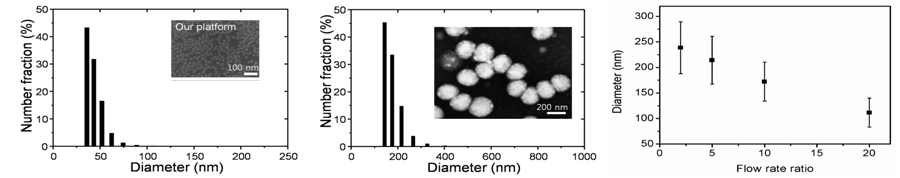

Liposome Size and Distribution

In the synthesis of liposome, it is possible to uniformly synthesize lipid vesicles of various sizes ranging from tens of nm to hundreds of nm depending on the composition ratio of the buffer solution and phospholipids, and the flow rate ratio of the buffer solution.

Liposome Synthesis Device : Advantages

The feedback function between the flow sensor and the drive motor allows the rpm of the drive motor to be controlled.

With the built-in liposome synthesis chip, vesicles of tens of nm to hundreds of nm in diameter can be uniformly synthesized at room temperature and atmospheric pressure.

Depending on the application, various phospholipids / amphiphilic polymers / surfactants can be used.

Device Specification

| Flow Rate Control | Minimum Flow Rate : 0.0015 mL/min Maximum Flow Rate : 18 mL/min |

|---|---|

| Lipid Vesicle Size | 30 nm ~ 500 nm |

| Throughput Rate | 10 mL/min ~ 1,500 mL/min |

| Microfluidic Chips | Membrane Type or Multichannel Type |

| Control Type | PLC Touch Control |

Applications: DDS, Cosmetics, Bio Sensors, Micro Reactors

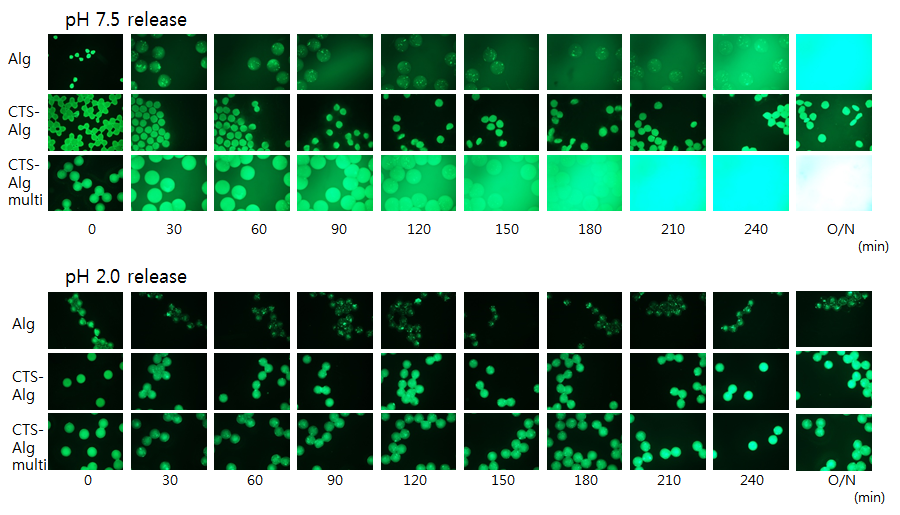

Example 1. Releasing time control of nano composites (Alginate/Chitosan) utilizing natural polymers

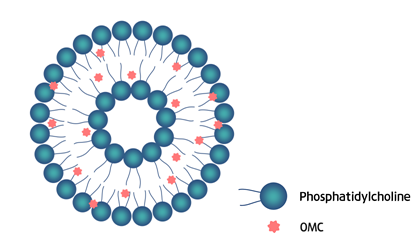

Example 2. Sunscreen AdditivesOctyl Methoxycinnamate (OMC)

Octyl Methoxycinnamate (OMC)

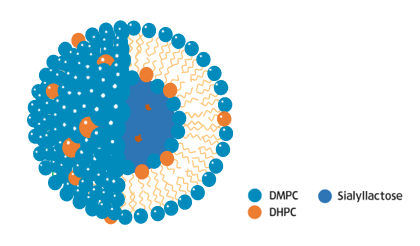

Example 3. Immune Boosters : Sialyllactose