본문

Nano·Micro Structure Chip Design & Manufacture(OEM/ODM)

Design & Modeling

Optimized design and analysis of fluid flowing models and structures of chambers, channels, inlets, outlets, etc.

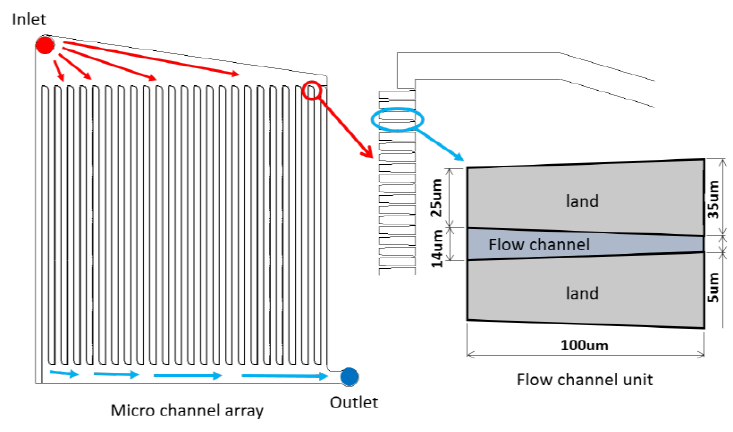

A Micro-Channel Design of a High Throughput Micro-fluidic Device for Screening Circulating Tumor Cells from the Blood Sample

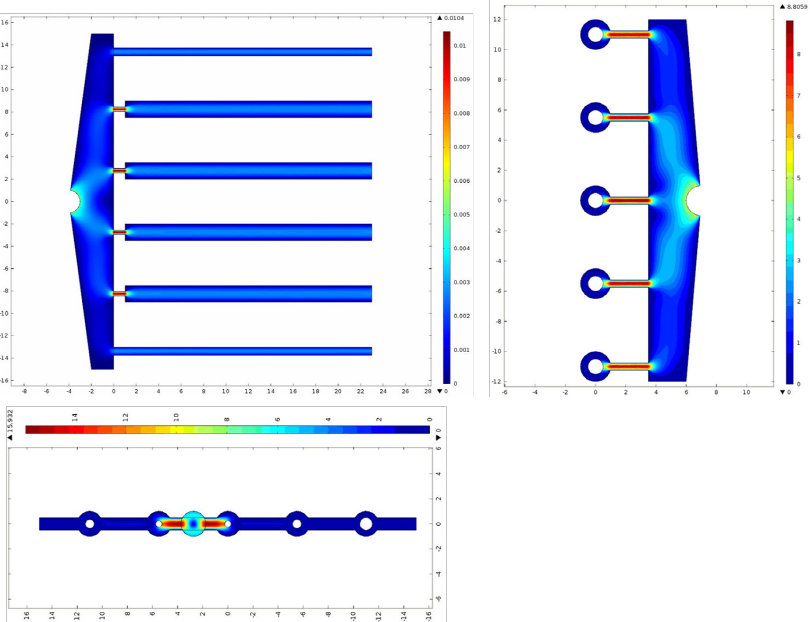

Numerical flow analysis for optimization of the micro-fluidic channel design to enhance the throughput of the fluid sample and the uniformity of the flow

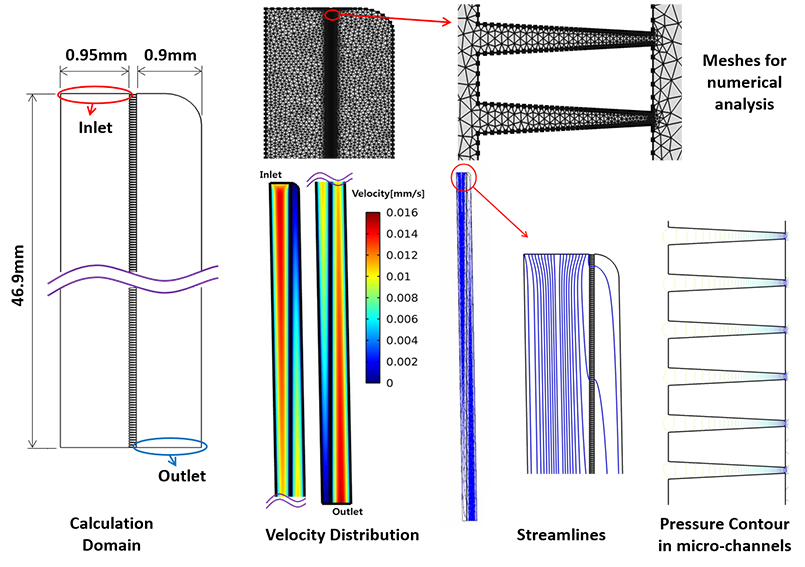

Numerical flow analysis and design optimization for the manifold of the multi-layer micro-fluidic device to deliver fluid sample uniformly to the micro-channels

Nano·Micro Patterned Stamper

Manufacturing nano/micro patterned molds utilizing MEMS technologies.

Core technology

Micro/nano patterns are transferred onto Si-wafer or Quartz by using semiconductor processes such as photolithography, scanner, laser direct writing, and Ni plating is performed according to the applications to provide Ni base molds.

Specifications

Pattern size: 100nm ~ hundreds of μm, aspect ratio < 3

Pattern shape: Pillar, Grating, Pinhole, Channel, etc.

Materials: Si-wafer, Quartz, Sodalime glass, Metal, etc

Application

microfluidic platforms for point-of-care testing, anti-reflective structures ect

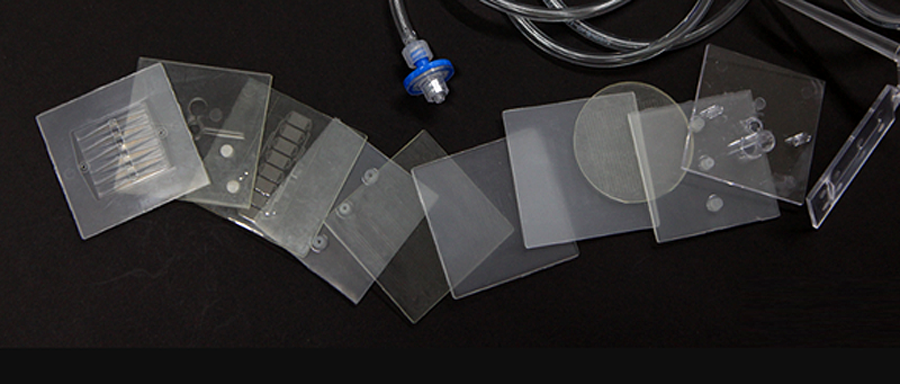

Nano·Micro Injection Molding

Microfluidic channels or MEMS based nano/micro platforms in polymers can be injection molded.

Core technology

Mass production of sophisticated plastic products such as microfluidic channels with higher productivity and yield by applying highly-precise molds equiped with rapid heating & cooling system.

Specifications

Pattern size: 100nm ~ hundreds of μm, aspect ratio < 5

Pattern shape: Pillar, Channel, etc.

Processing area: 30mm×30mm ~ 400mm×400mm

Materials: PMMA, PC, PP, COC, TPU, etc.

Heating & cooling systems on molds

Application

Microfluidic channels for various in-vitro diagnostic and point-of-care testing devices

Bio-MEMS

liposome synthesis device

Assembly-Packaging

Packaging technology for plastic-plastic, film-plastic, plastic-wafer, and film-wafer is the finishing process of injection molded parts. It shows excellent sealing and bonding properties, which has been technologically invested by Korea Institute of Machinery & Materials as follows.

Package way

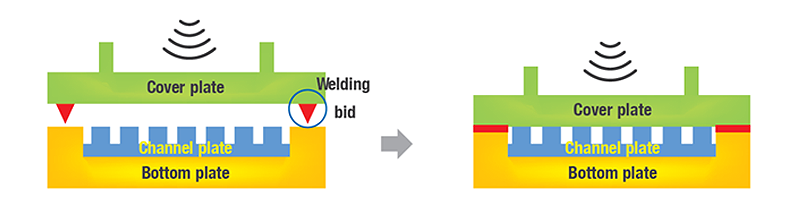

Packaging by Ultrasonic Welding & Mechanical Contact

Hermetic sealing

Good adhesion

Good success rate(> 95%)

Good productivity (cycle time ~ 15 sec)

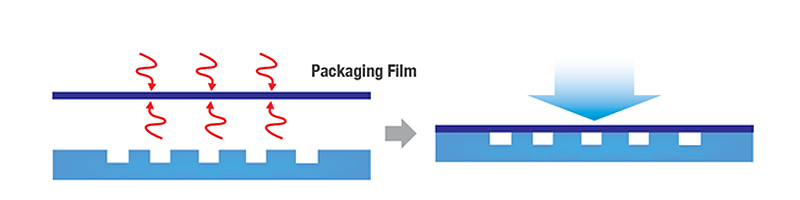

Packaging by Film Thermal Lamination

Typical packaging for microfluidic platforms currently

Good for a handy device

A Reversible Packaging Solution

Uniform contact pressure at the interface

Hermetic sealing

Controllable sealing level during operation

Excellent success rate(~ 100%) and productivity (< a few seconds)

Very short lead time for packaging

Application

Packaging for microfluidic channel based devices, and MEMS or Bio-MEMS based devices